Facilities

Facilities

Instrumentation

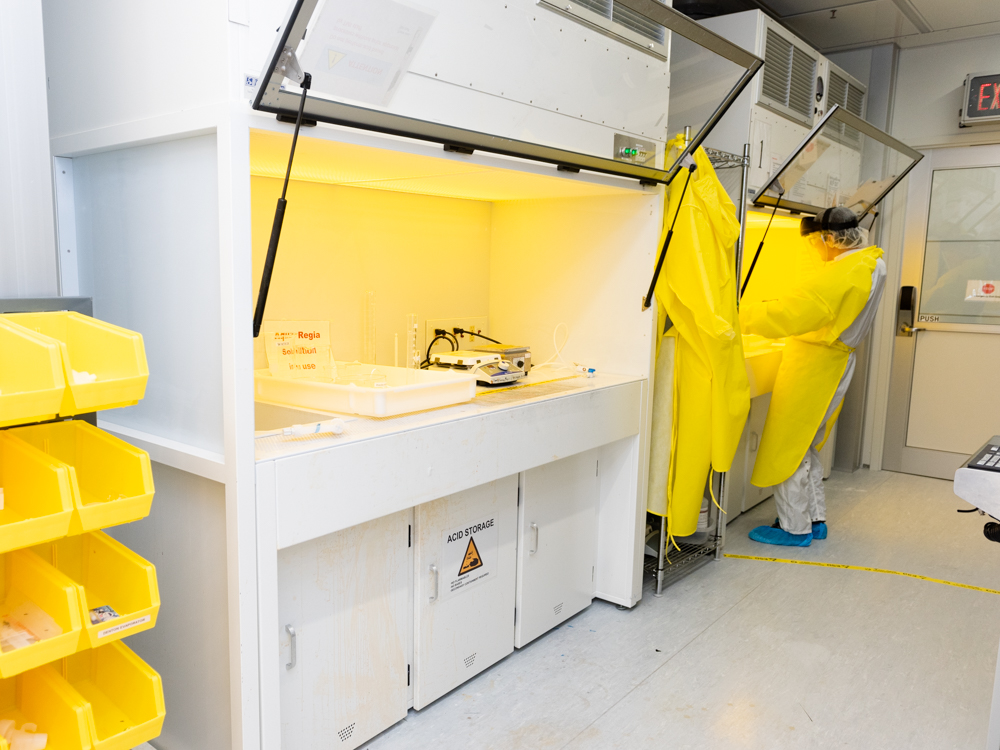

Acids Hood

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Acids Hood

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Aixtrom Black Magic

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Plasma Etching and Material Growth

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

AM Scope

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

AMOD Thermal Deposition System

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

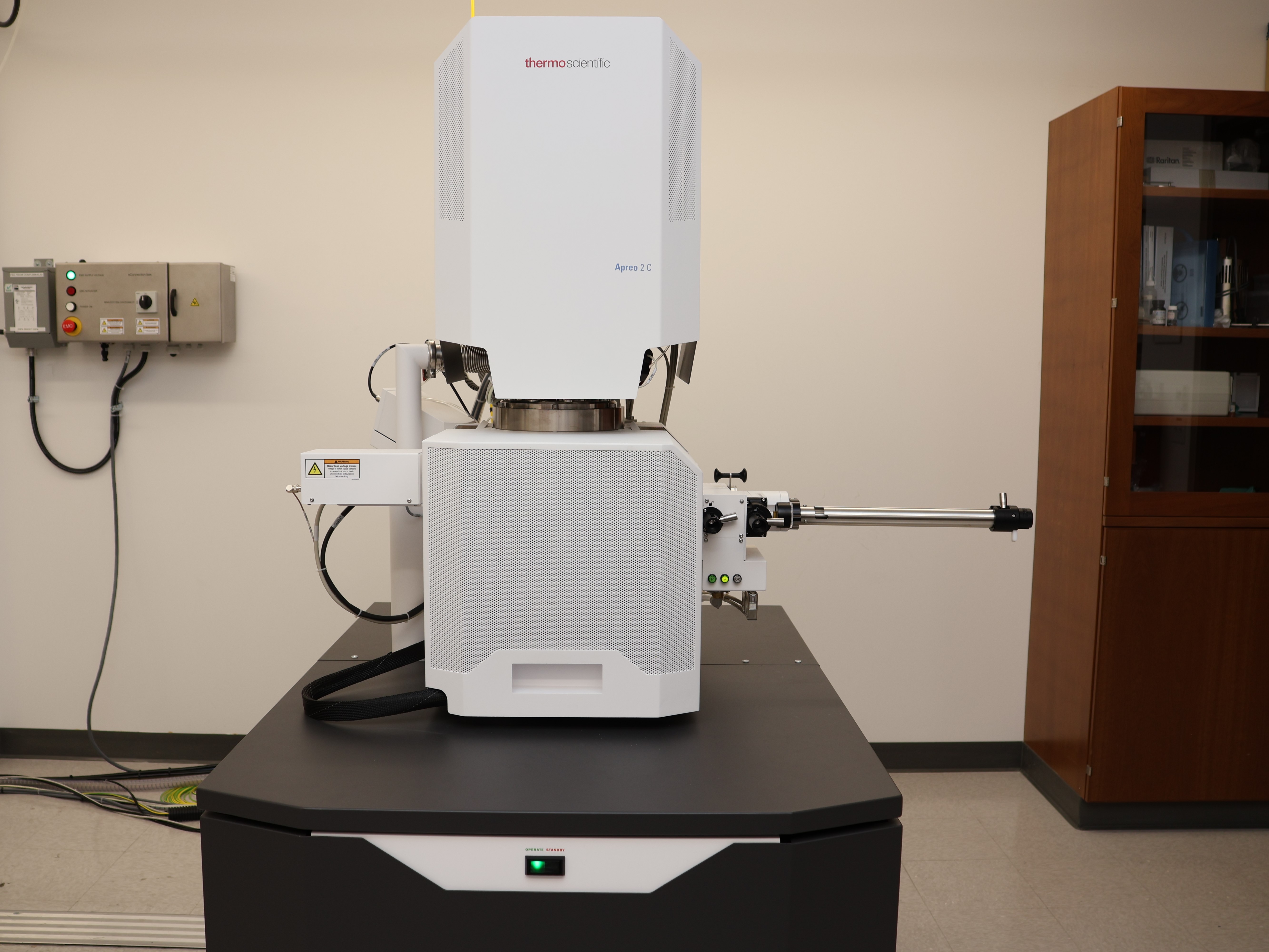

Apreo 2C LoVac SEM

Equipment Type:

Electron Microscopy

Microscopy/Surface Analysis

Scanning Electron Microscopes (SEM)

Contact: Dr. Andrei Dolocan

Location: EER 0.752

View Details

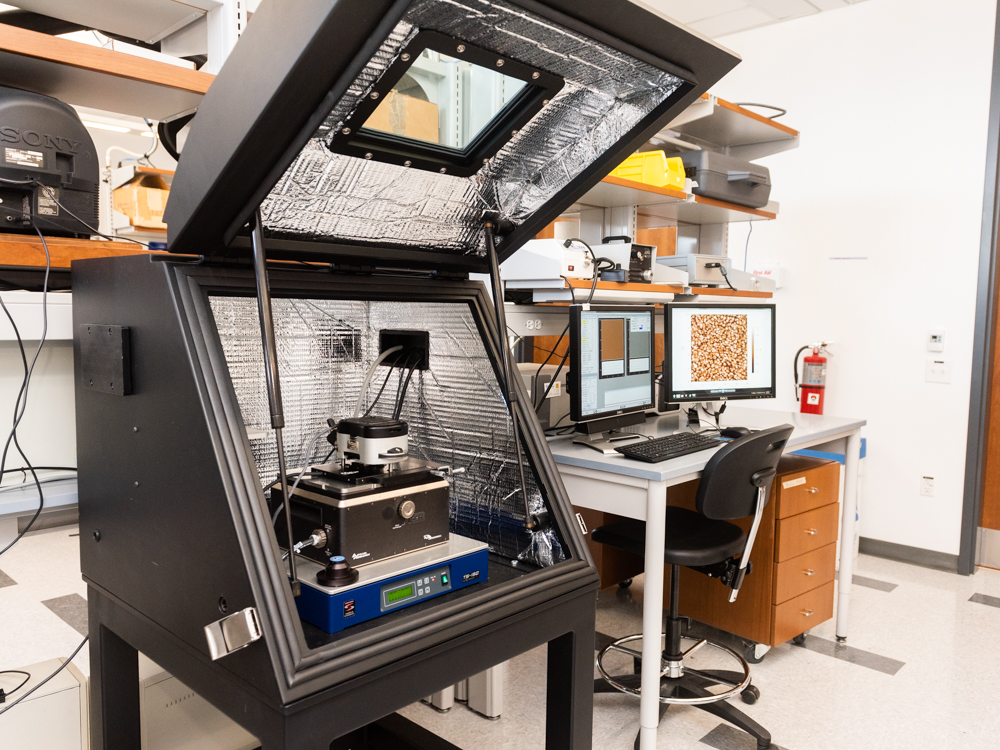

Asylum MFP-3D AFM

Equipment Type:

Atomic Force Microscopes

Metrology

Microscopy/Surface Analysis

Contact: Dr. Raluca Gearba

Location: EER 6.628

View Details

Atomic Force Microscopes

Equipment Type:

Atomic Force Microscopes

Microscopy/Surface Analysis

Contact: Dr. Raluca Gearba

Location: EER 6.626

View Details

Bruker Invernio R FTIR

Equipment Type:

Polymer Characterization

Spectroscopy

Contact: Dr. Hugo Celio

Location: EER 6.640

View Details

Cambridge Nanotech Savannah TM200 ALD

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

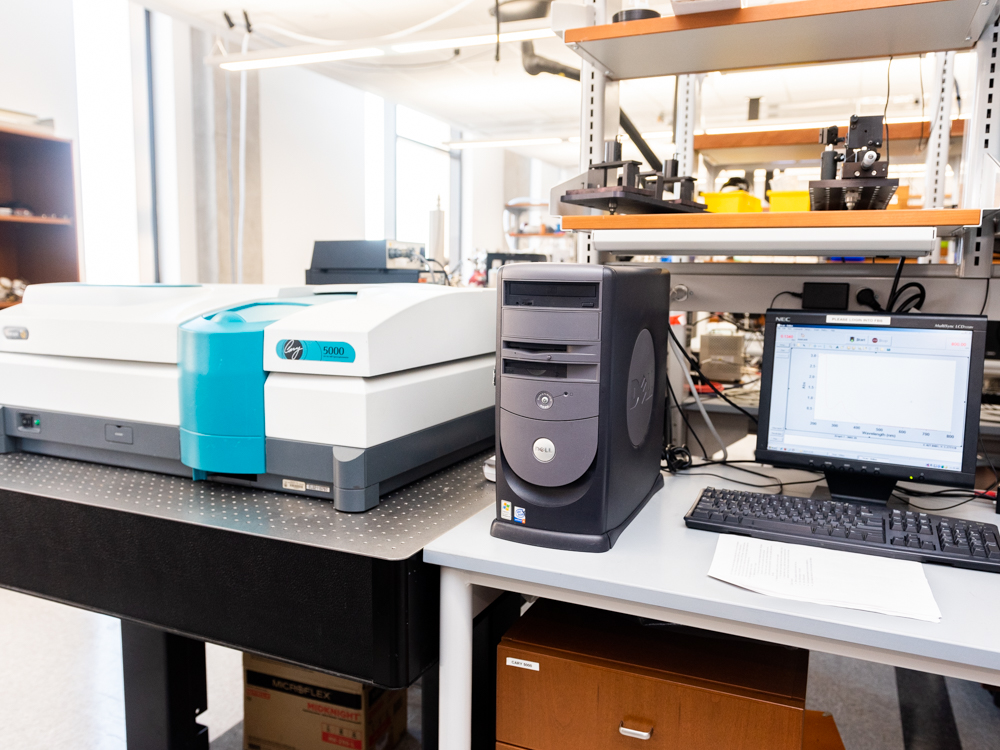

Cary 5000 UV/Vis NIR

Equipment Type:

Spectroscopy

Contact: Dr. Raluca Gearba

Location: EER 6.644

View Details

Cleanroom Instrumentation

Equipment Type:

Cleanroom Instrumentation

Metrology

Nano and Micro Fabrication

Plasma Etching and Material Growth

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Contact Angle Goniometer

Equipment Type:

Cleanroom Instrumentation

Metrology

Surface Analysis

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Cooke e-beam and Sputtering System

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Dektak 6M Stylus Profilometer

Equipment Type:

Cleanroom Instrumentation

Metrology

Microscopy/Surface Analysis

Surface Analysis

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Denton Thermal Evaporator

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Disco 321 Wafer Dicing Saw

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Dynamic Light Scattering Zetasizer Nano ZS

Equipment Type:

Polymer Characterization

Contact: Dr. Hugo Celio

Location: 6.640

View Details

Electrical Characterization Instrumentation

Equipment Type:

Cleanroom Instrumentation

Electrical Characterization Instrumentation

Electronic and Optoelectronic Testing

Contact: Dr. Raluca Gearba

Location: FNT 4.102

View Details

EMS Sputter Coater

Equipment Type:

Thin Film Fabrication

Contact: Dr. Andrei Dolocan

Location: EER 0.752

View Details

FEI Quanta 650 ESEM

Equipment Type:

Electron Microscopy

Microscopy/Surface Analysis

Scanning Electron Microscopes (SEM)

Contact: Dr. Andrei Dolocan

Location: EER 6.628

View Details

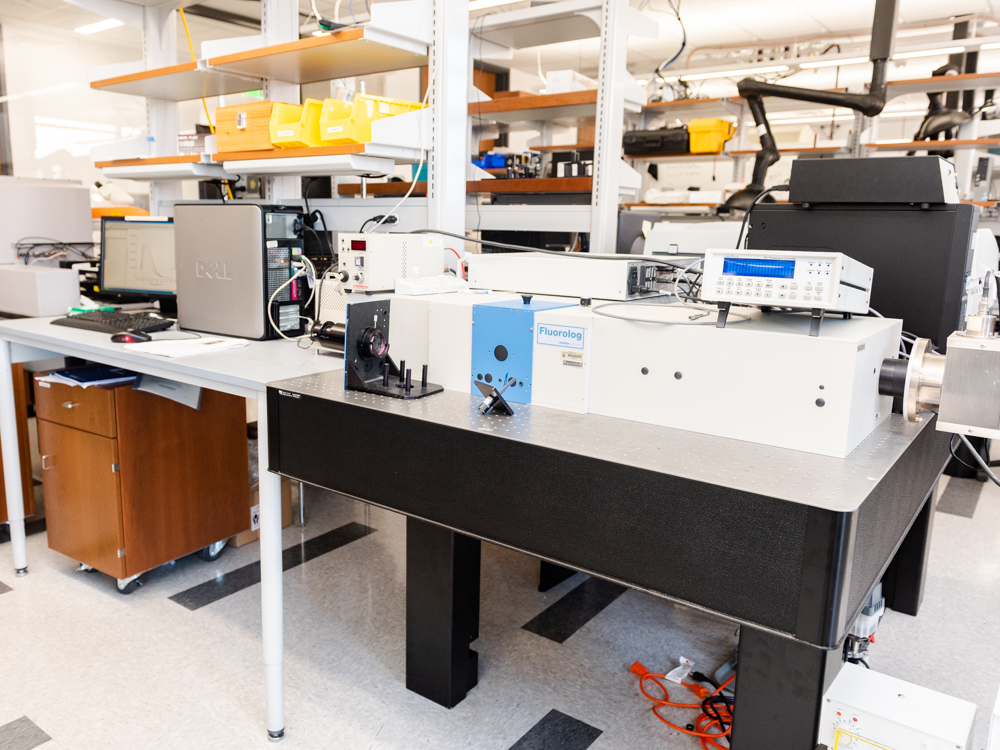

Fluorolog3 Fluorimeter

Equipment Type:

Spectroscopy

Contact: Dr. Raluca Gearba

Location: EER 6.644

View Details

Fuljifilm DMP-2800 Dimatix Printer

Equipment Type:

Cleanroom Instrumentation

Lithography

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Gatan 691 Precision Ion-Miller

Equipment Type:

TEM Sample Preparation

Contact: Dr. Xun Zhan

Location: EER 0.922

View Details

HF Hood

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

HF Hood

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Hitachi IM4000C Broad Beam Ion Milling System

Equipment Type:

Nano and Micro Fabrication

Contact: Dr. Hugo Celio

Location: EER 6.636

View Details

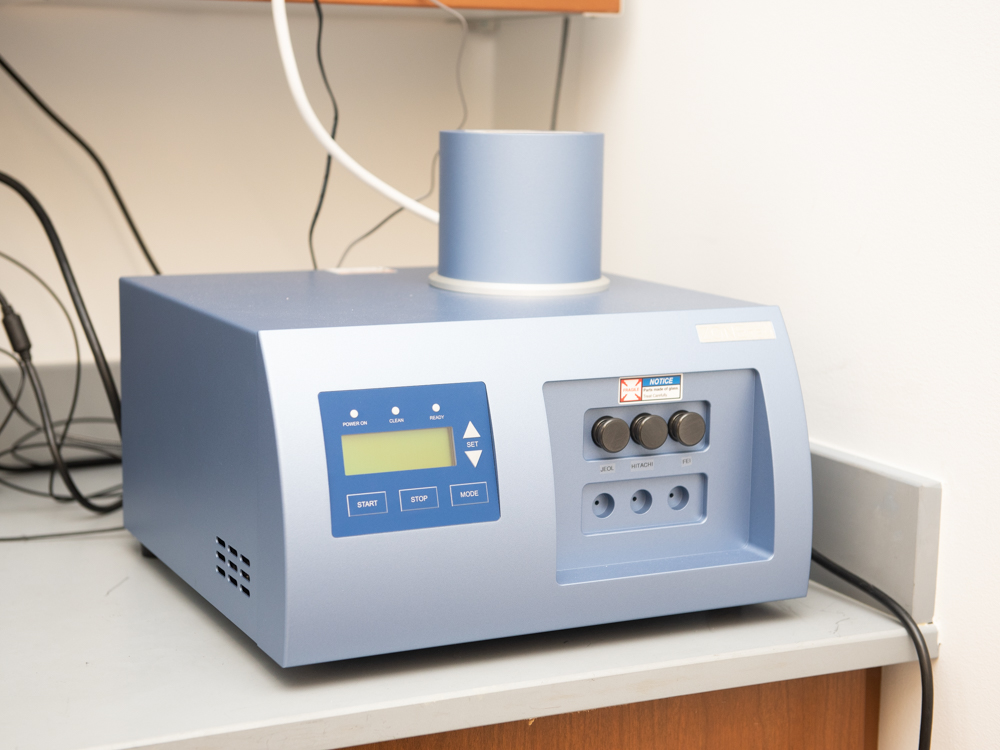

Hitachi Ozone Cleaner

Equipment Type:

TEM Sample Preparation

Contact: Dr. Xun Zhan

Location: EER 0.752

View Details

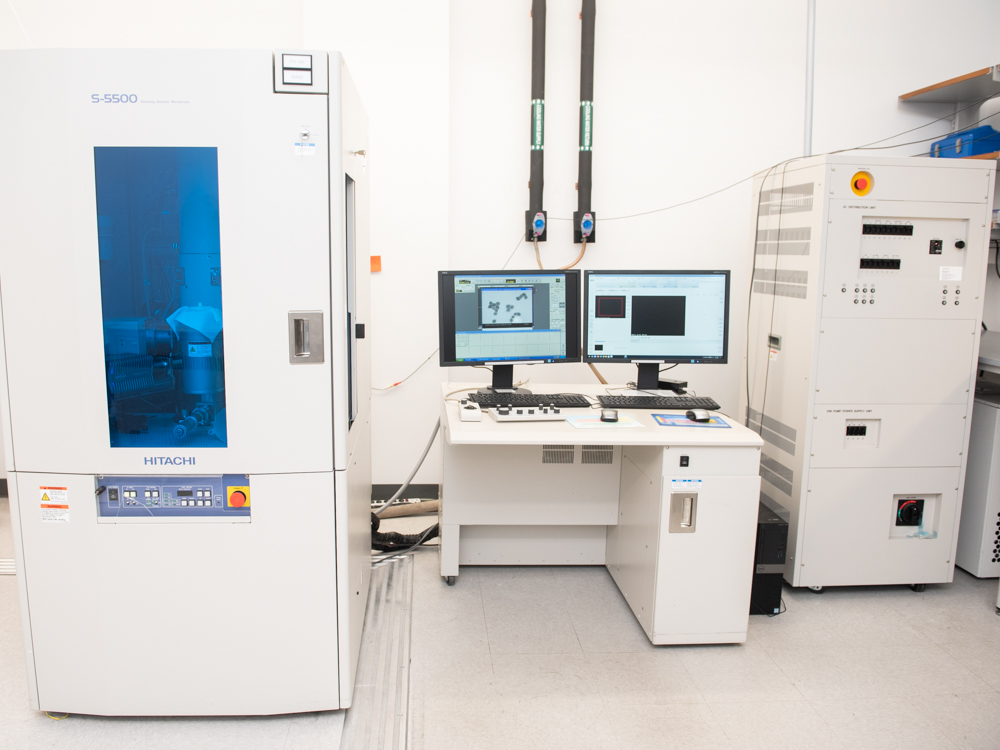

Hitachi S-5500 SEM/STEM

Equipment Type:

Electron Microscopy

Scanning Electron Microscopes (SEM)

Contact: Dr. Andrei Dolocan

Location: EER 0.752

View Details

HMDS YES OVEN

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Hood for Handling Powder Materials

Equipment Type:

Scanning Electron Microscopes (SEM)

TEM Sample Preparation

Contact: Dr. Raluca Gearba

Location: EER 6.628

View Details

Hood for STM and TEM Sample Prep

Equipment Type:

Microscopy/Surface Analysis

TEM Sample Preparation

Contact: Dr. Raluca Gearba

Location: EER 0.746

View Details

Hysitron TI-950 Triboindenter

Equipment Type:

Metrology

Contact: Dr. Raluca Gearba

Location: EER 6.628

View Details

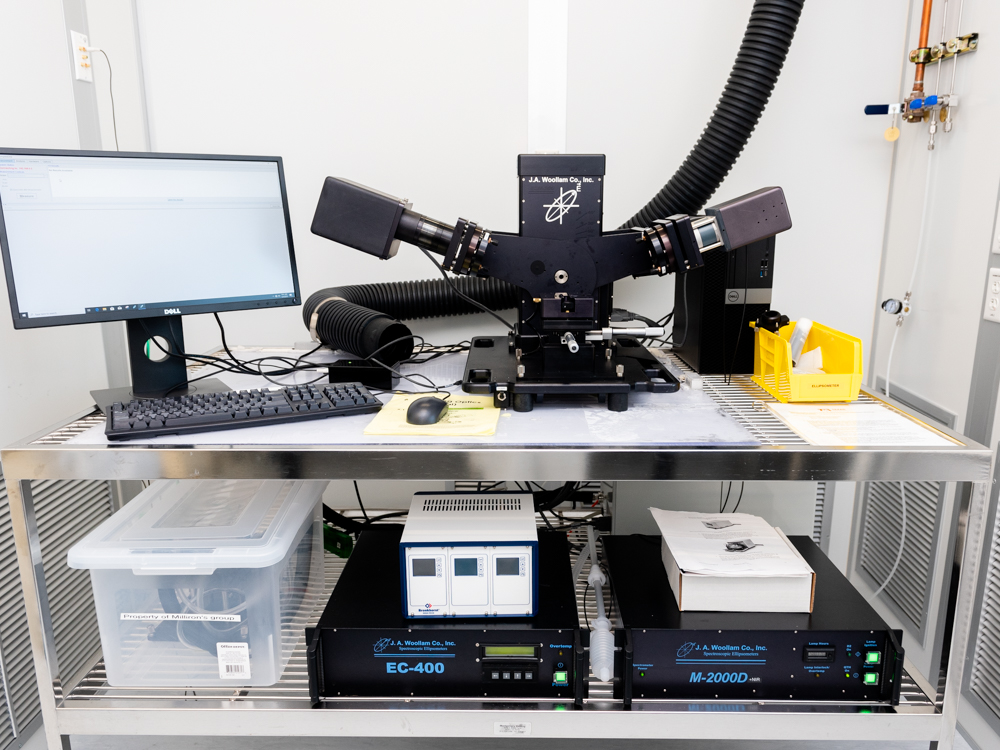

J.A. Wollam M2000 Spectroscopic Ellipsometer

Equipment Type:

Cleanroom Instrumentation

Metrology

Spectroscopy

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

JEOL NEOARM Low kV STEM Corrected

Equipment Type:

Electron Microscopy

Transmission Electron Microscopy (TEM)

Contact: Dr. Xun Zhan

Location: EER 0.762

View Details

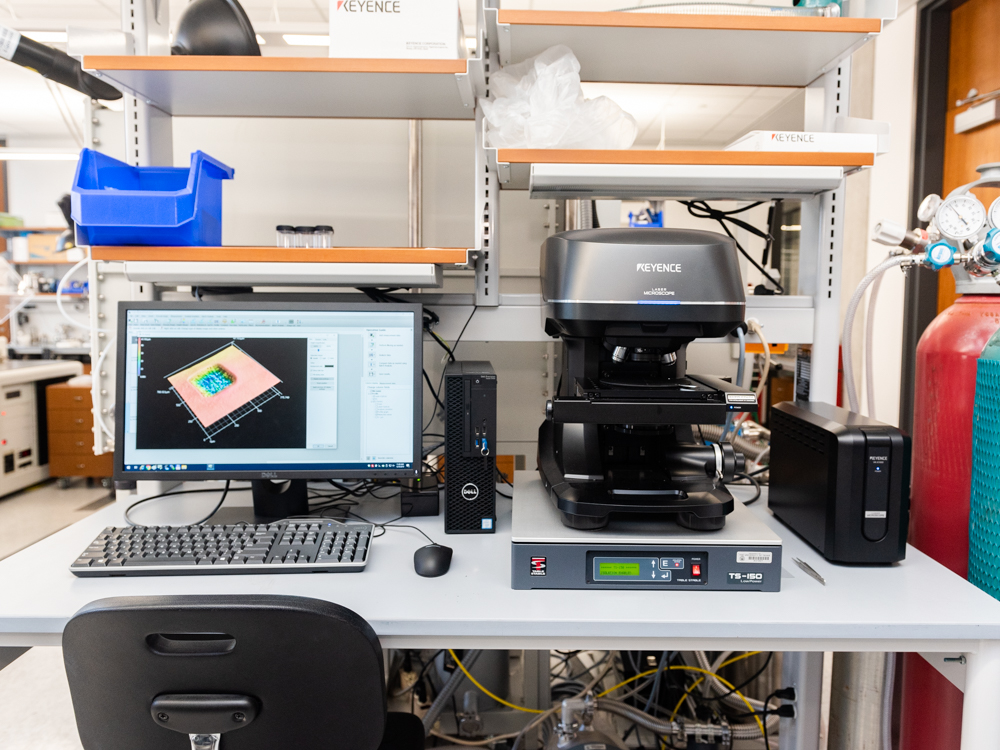

Keyence VK-X1100 Optical Profilometer

Equipment Type:

Microscopy/Surface Analysis

Optical Profiles

Surface Analysis

Contact: Dr. Andrei Dolocan

Location: EER 6.636

View Details

KLA P-7 Stylus Profilometer

Equipment Type:

Cleanroom Instrumentation

Metrology

Microscopy/Surface Analysis

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

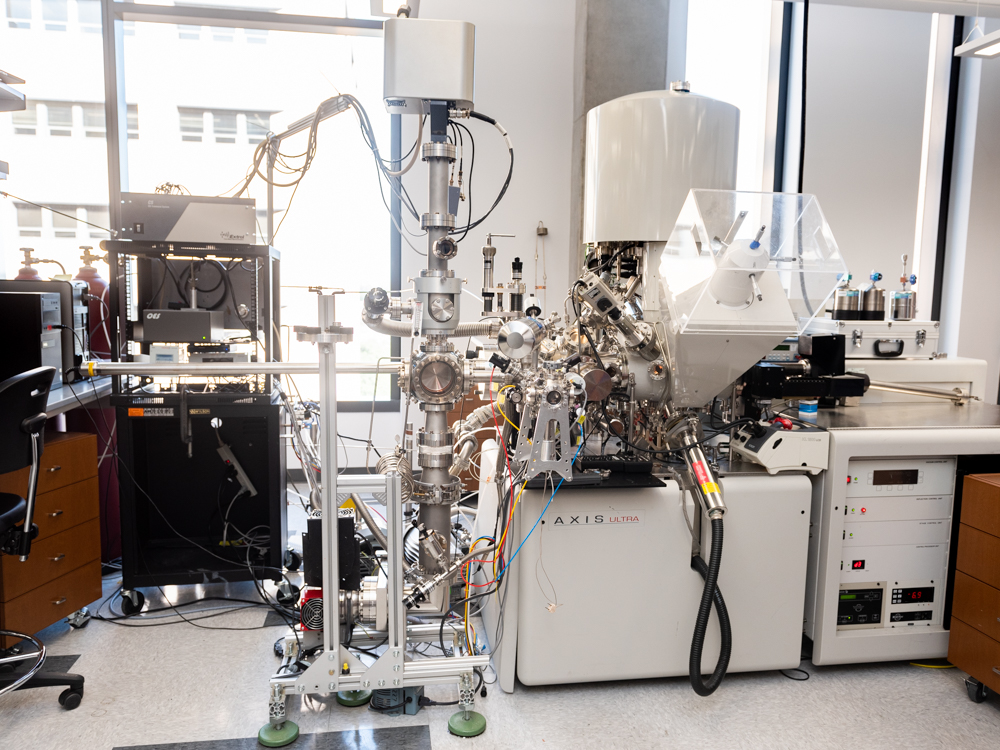

Kratos X-ray Photoelectron Spectrometer – Axis Ultra DLD

Equipment Type:

Microscopy/Surface Analysis

Surface Analysis

Contact: Dr. Hugo Celio

Location: EER 6.636

View Details

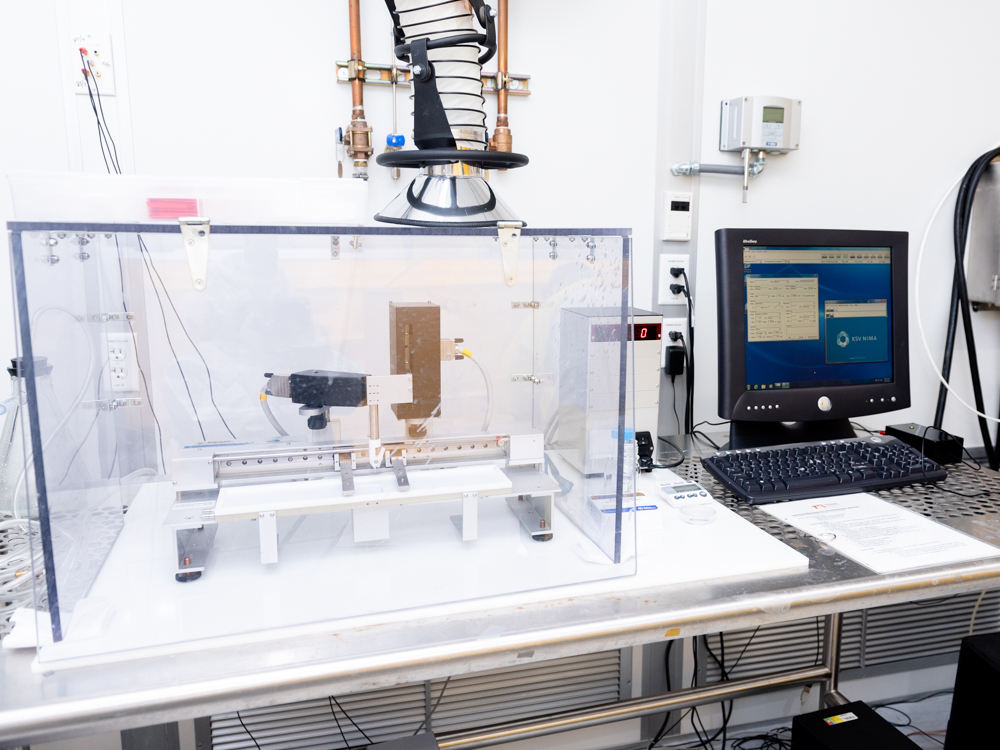

KSV Langmuir-Blodgett Trough

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Kurt J Lesker Nano36 Thermal Deposition System

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Laurell Technologies Spincoater I

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Laurell Technologies Spincoater II

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: EER 6.626

View Details

Laurell Technologies Spincoater III

Equipment Type:

Microscopy/Surface Analysis

Spectroscopy

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: EER 6.628

View Details

Leica Cryo Setup

Equipment Type:

Electron Microscopy

TEM Sample Preparation

Contact: Dr. Raluca Gearba

Location: EER 6.644

View Details

Leica EM TIC 3X

Equipment Type:

Microscopy/Surface Analysis

TEM Sample Preparation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: EER 6.644

View Details

March Plasma CS170IF RIE Etching System

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Plasma Etching and Material Growth

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

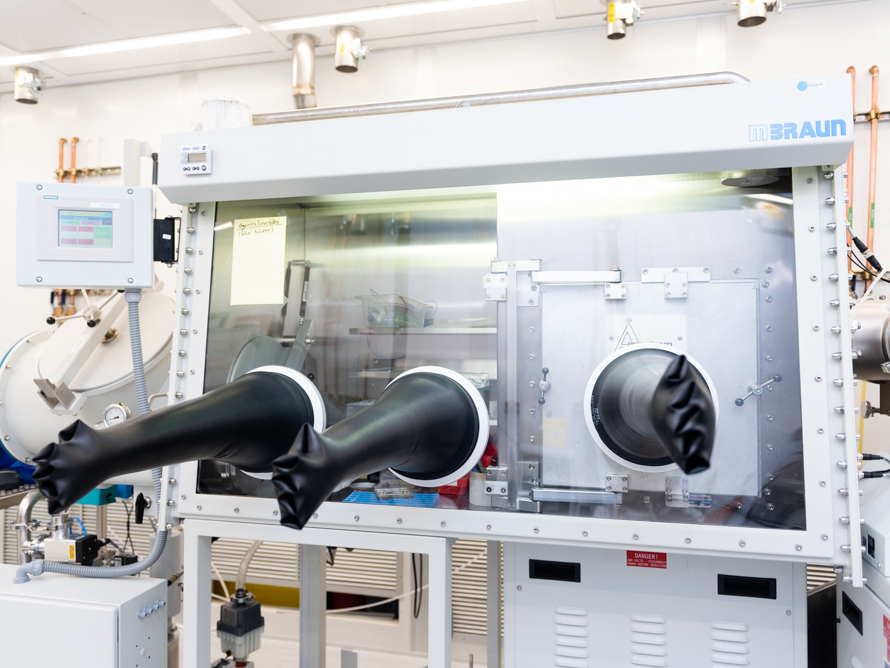

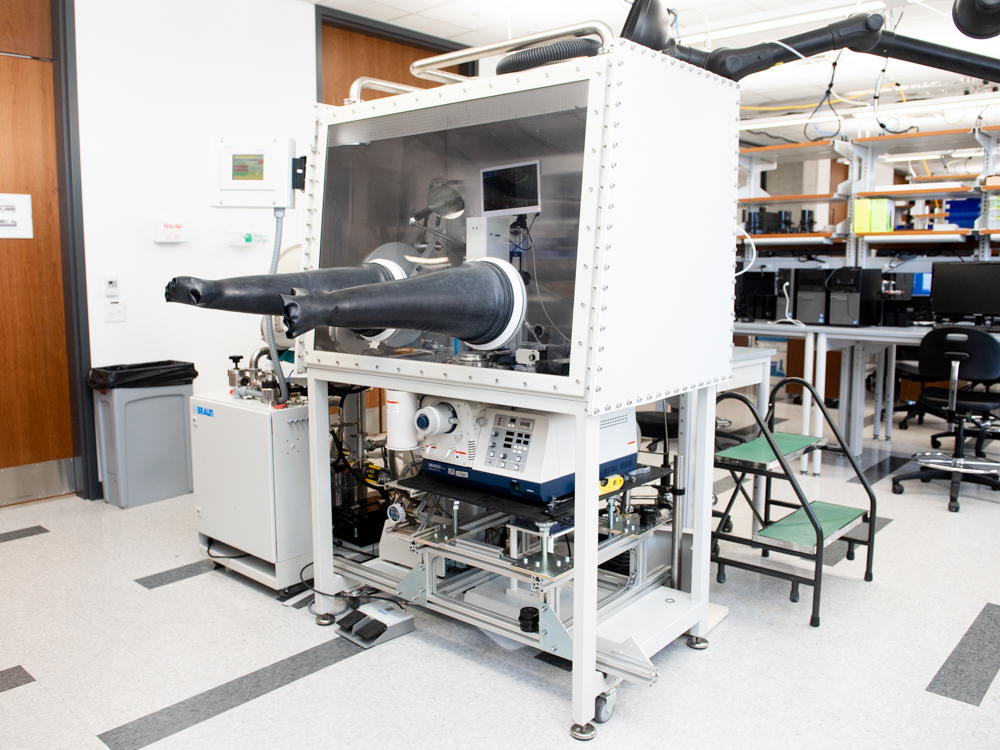

MBraun Nitrogen Glovebox

Equipment Type:

Microscopy/Surface Analysis

Contact: Dr. Raluca Gearba

Location: EER 6.628

View Details

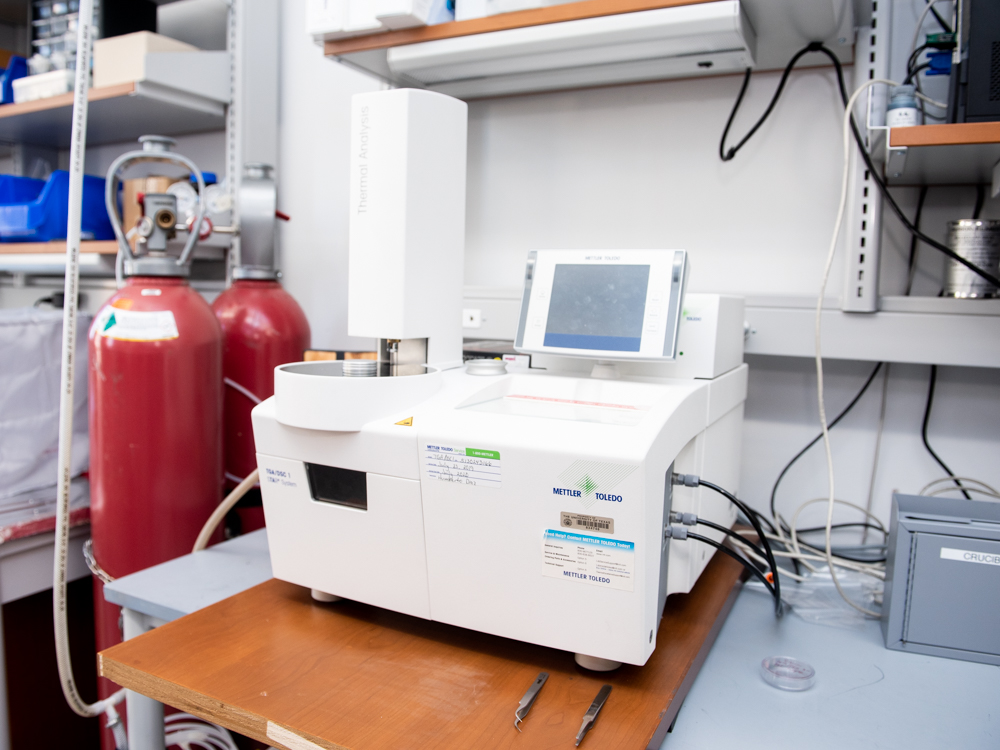

Mettler Thermogravimetric Analyzer, Model TGA/DSC 1

Equipment Type:

Polymer Characterization

Contact: Dr. Hugo Celio

Location: EER 6.636

View Details

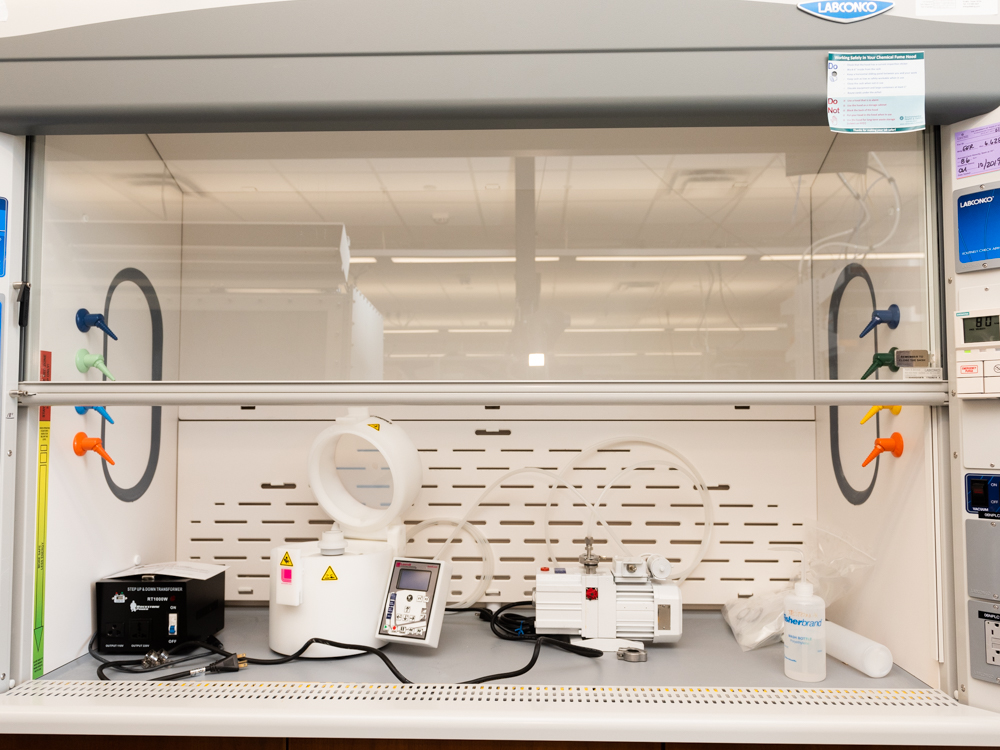

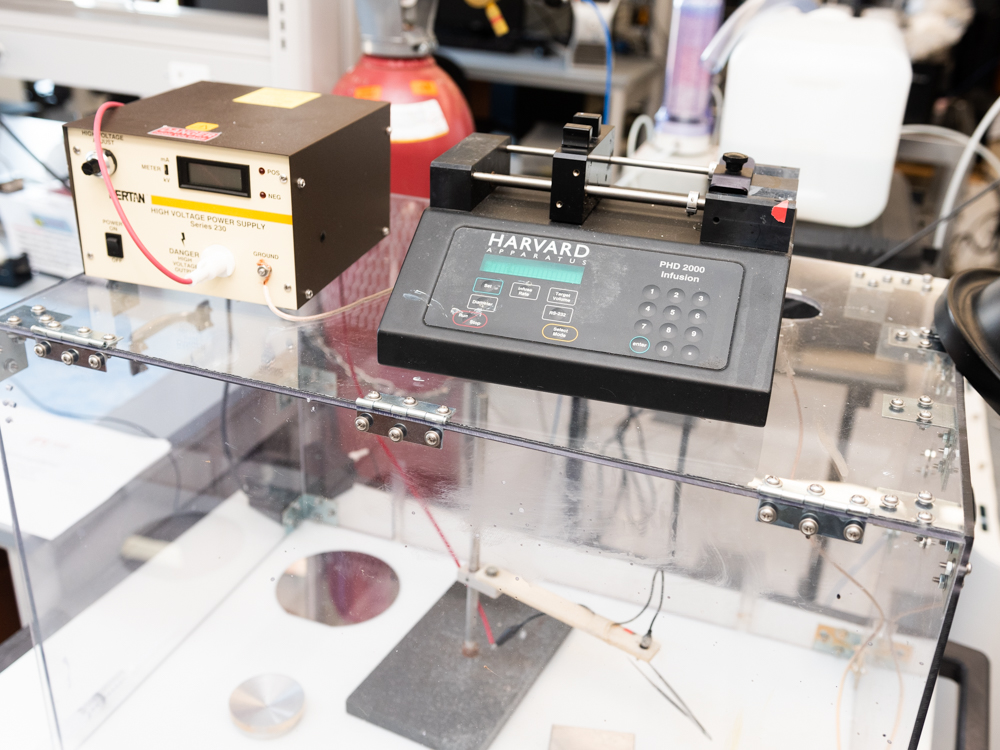

Nano/Microfiber Electrospinning System

Equipment Type:

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: EER 6.644

View Details

Nordson March PX-250 RIE

Equipment Type:

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Omicron LT-STM/SPM

Equipment Type:

Microscopy/Surface Analysis

Scanning Tunneling Microscopes (STM)

Surface Analysis

Contact: Dr. Raluca Gearba

Location: EER 0.746

View Details

Oxford Instruments Plasma Lab 80+ PECVD and Etching

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Plasma Etching and Material Growth

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Park Systems NX10 AFM

Equipment Type:

Atomic Force Microscopes

Microscopy/Surface Analysis

Location: EER 6.628

View Details

Plasma Therm 790 RIE/ICP/PECVD

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

PVD75 e-beam and Sputtering System

Equipment Type:

Cleanroom Instrumentation

Thin Film Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

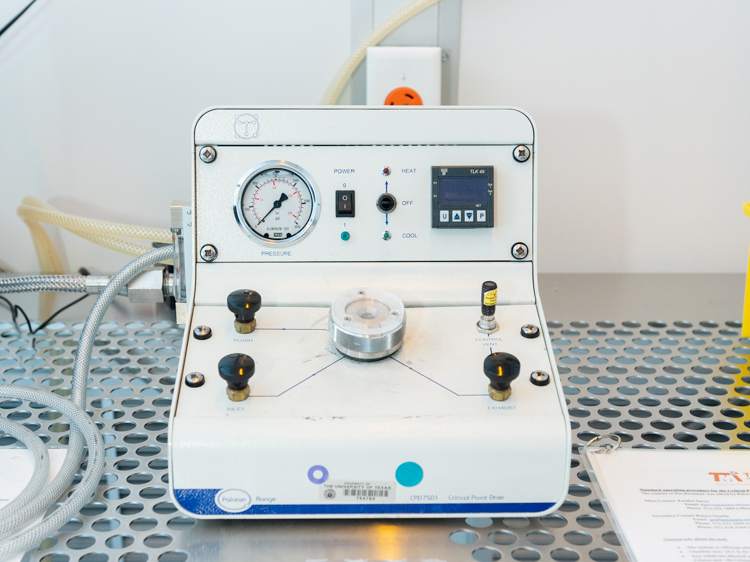

Quorum Technologies Critical Point Drier

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Raith 150 Two E-beam Lithography

Equipment Type:

Lithography

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Renishaw InVia Reflex Raman Spectrometer

Equipment Type:

Micro Raman Spectra

Contact: Dr. Raluca Gearba

Location: EER 6.644

View Details

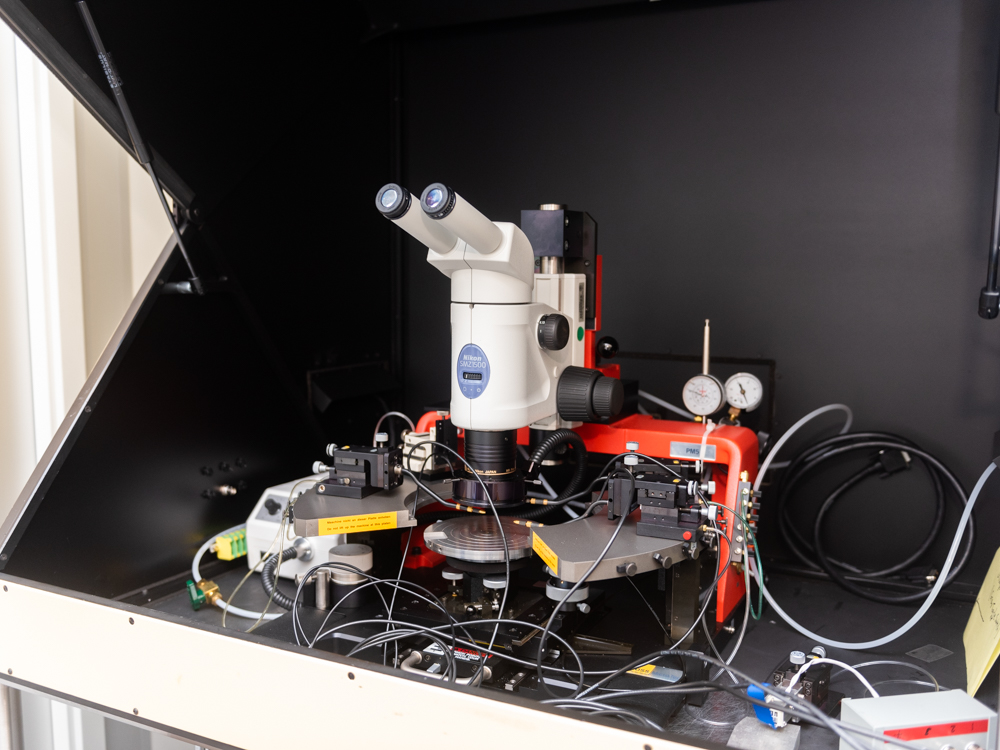

RHK ATM 300 STM

Equipment Type:

Microscopy/Surface Analysis

Scanning Tunneling Microscopes (STM)

Contact: Dr. Raluca Gearba

Location: EER 6.628

View Details

Rigaku Miniflex 600 Diffractometer I

Equipment Type:

X-ray Diffraction

X-ray Scattering

Contact: Dr. Steve Swinnea

Location: EER 6.640

View Details

Rigaku Miniflex 600 Diffractometer II

Equipment Type:

X-ray Diffraction

X-ray Scattering

Contact: Dr. Steve Swinnea

Location: EER 6.640

View Details

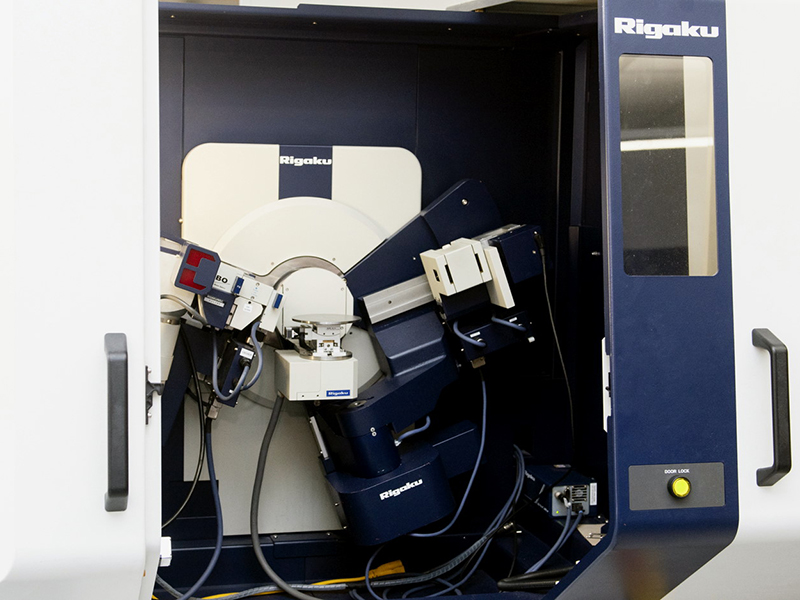

Rigaku ULTIMA IV Diffractometer

Equipment Type:

X-ray Diffraction

X-ray Scattering

Contact: Dr. Steve Swinnea

Location: EER 6.640

View Details

Samco RIE-1C Reactive Ion Etcher

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Plasma Etching and Material Growth

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

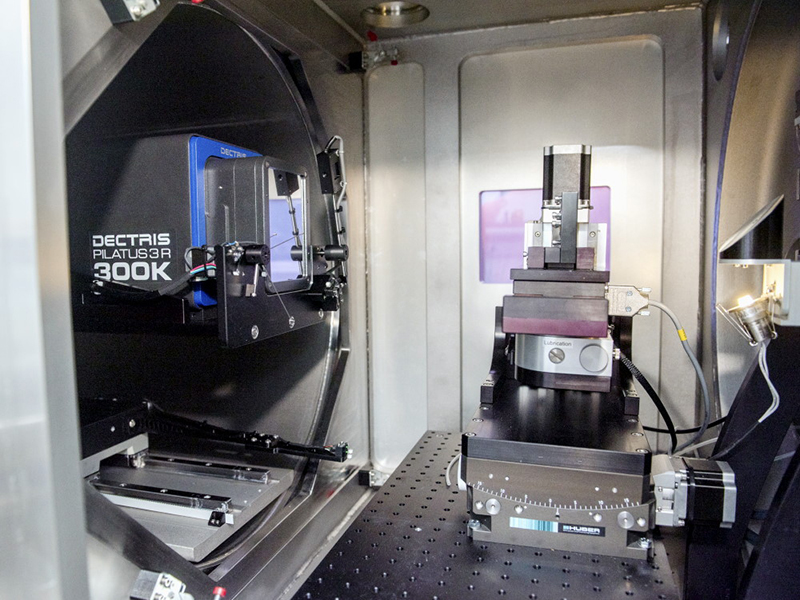

SAXSLabs Ganesha

Equipment Type:

SAXS

X-ray Scattering

Contact: Dr. Steve Swinnea

Location: EER 6.640

View Details

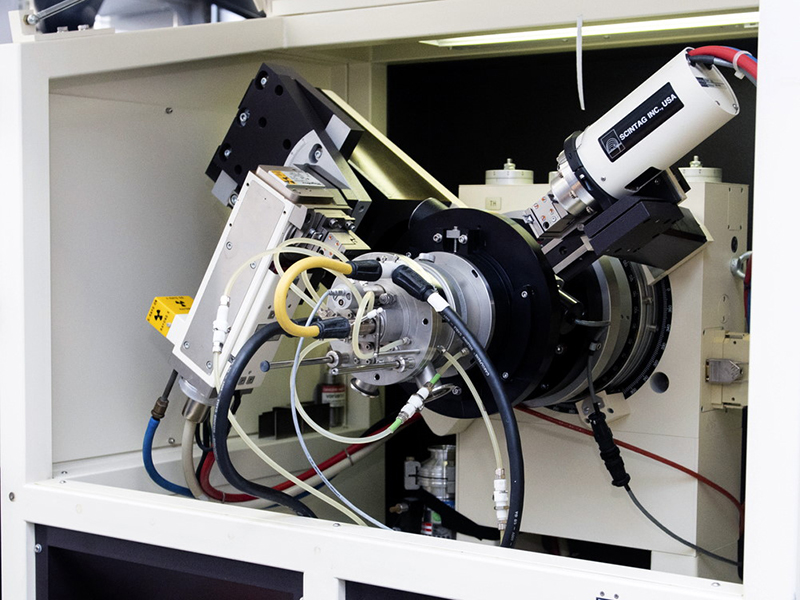

Scintag X1 Theta-Theta Diffractometer

Equipment Type:

X-ray Diffraction

Contact: Dr. Steve Swinnea

Location: EER 6.640

View Details

Scios 2HiVac Dual beam FIB/SEM System with EBL Capabilities

Equipment Type:

Electron Microscopy

Nano and Micro Fabrication

TEM Sample Preparation

Contact: Dr. Raluca Gearba

Location: EER 0.756

View Details

Solar Cells Testing Glovebox

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Suss MA6 Mask Aligner

Equipment Type:

Cleanroom Instrumentation

Lithography

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

Suss MA6 Mask Aligner (system 2)

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

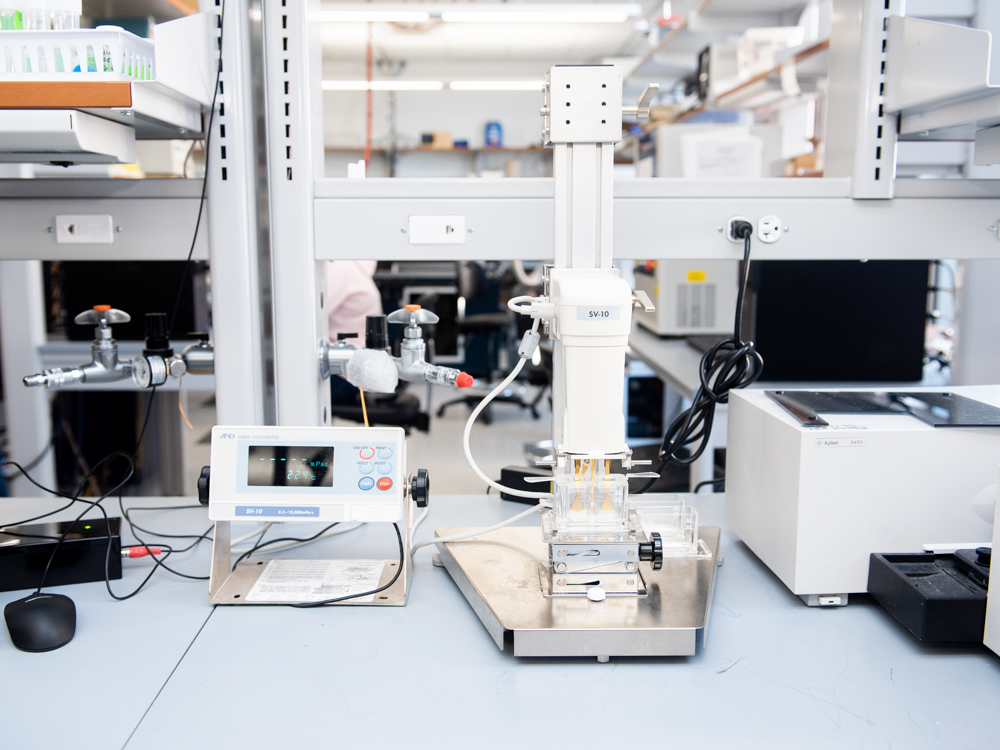

SV-10 Viscometer

Equipment Type:

Polymer Characterization

Contact: Dr. Hugo Celio

Location: EER 6.640

View Details

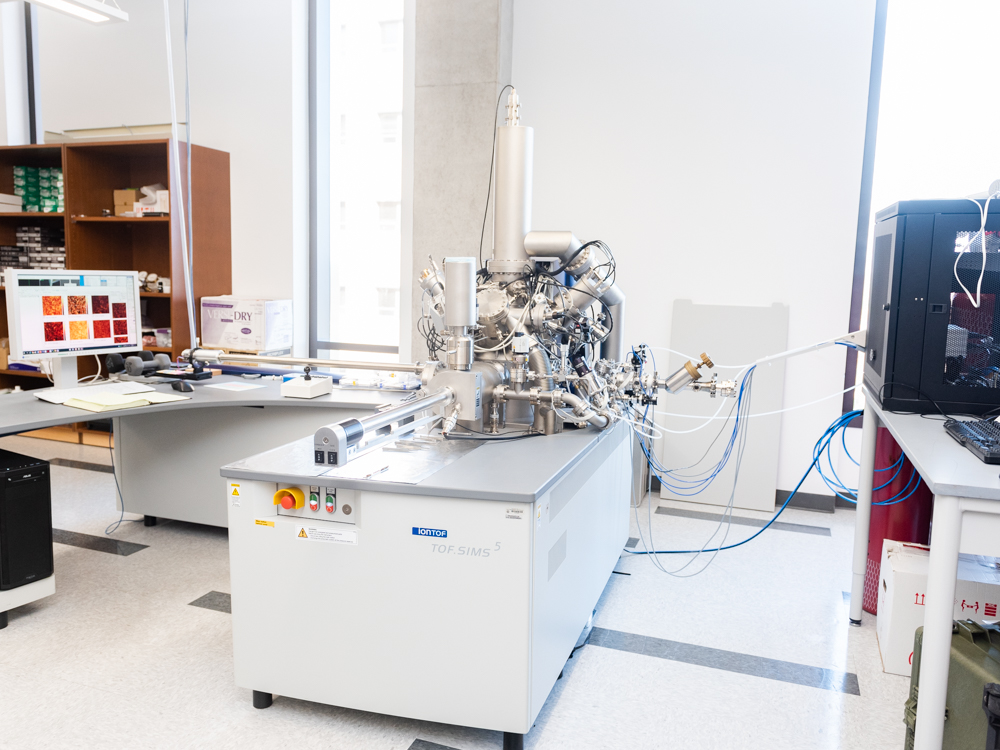

Time of Flight Secondary Ion Mass Spectrometer (TOF.SIMS 5)

Equipment Type:

Microscopy/Surface Analysis

Surface Analysis

Contact: Dr. Andrei Dolocan

Location: EER 6.636

View Details

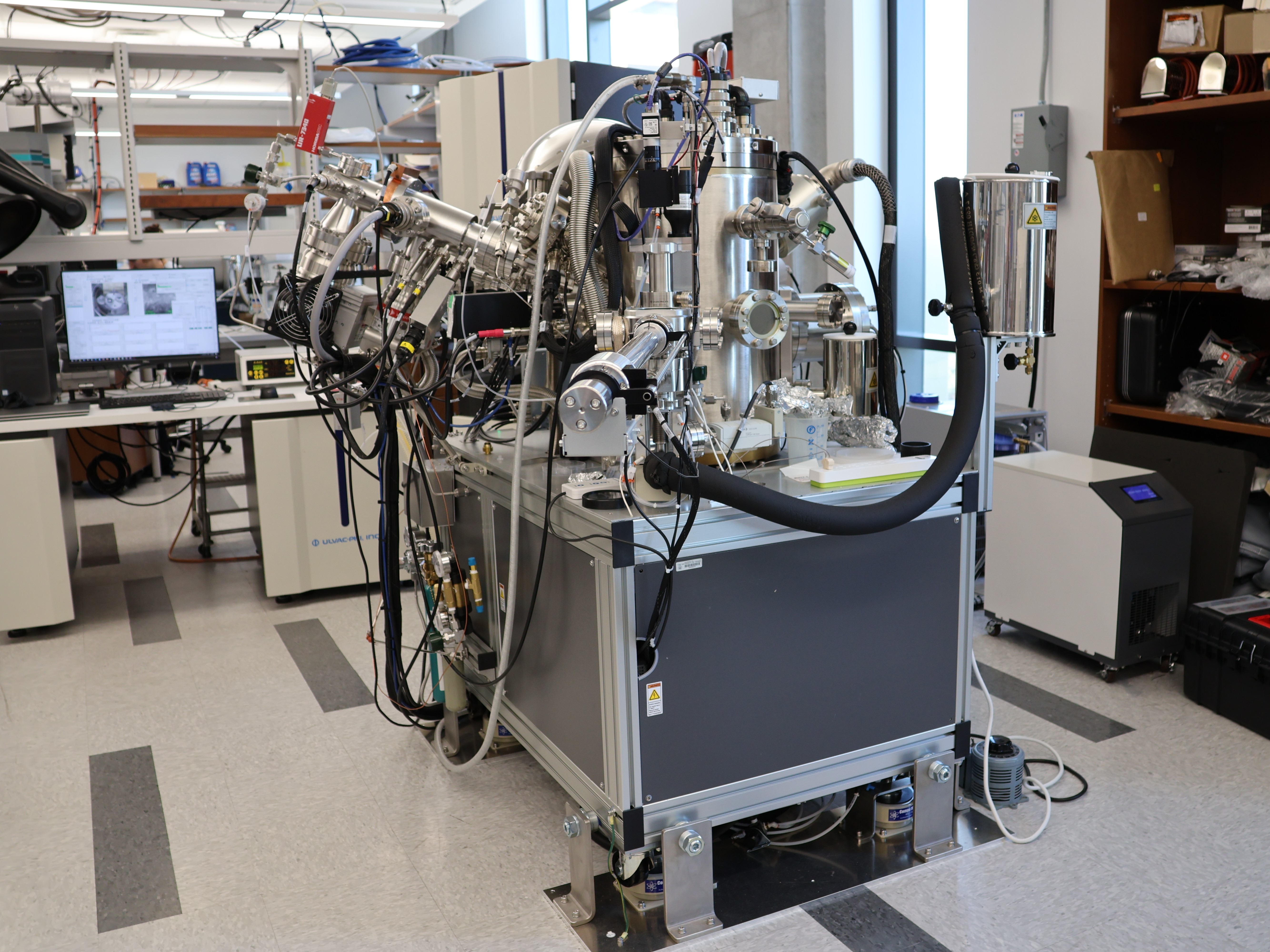

Time of Flight Secondary Ion Mass Spectrometer (TOF.SIMS M6)

Equipment Type:

Microscopy/Surface Analysis

Surface Analysis

Contact: Dr. Andrei Dolocan

Location: EER 6.636

View Details

Vacuum Ovens

Equipment Type:

Cleanroom Instrumentation

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

VersaProbe4 X-ray Photoelectron Spectrometer

Equipment Type:

Microscopy/Surface Analysis

Surface Analysis

Contact: Dr. Hugo Celio

Location: EER 6.636

View Details

West Bond Wire Bonder

Equipment Type:

Cleanroom Instrumentation

Electronic and Optoelectronic Testing

Nano and Micro Fabrication

Contact: Dr. Raluca Gearba

Location: FNT 4.106

View Details

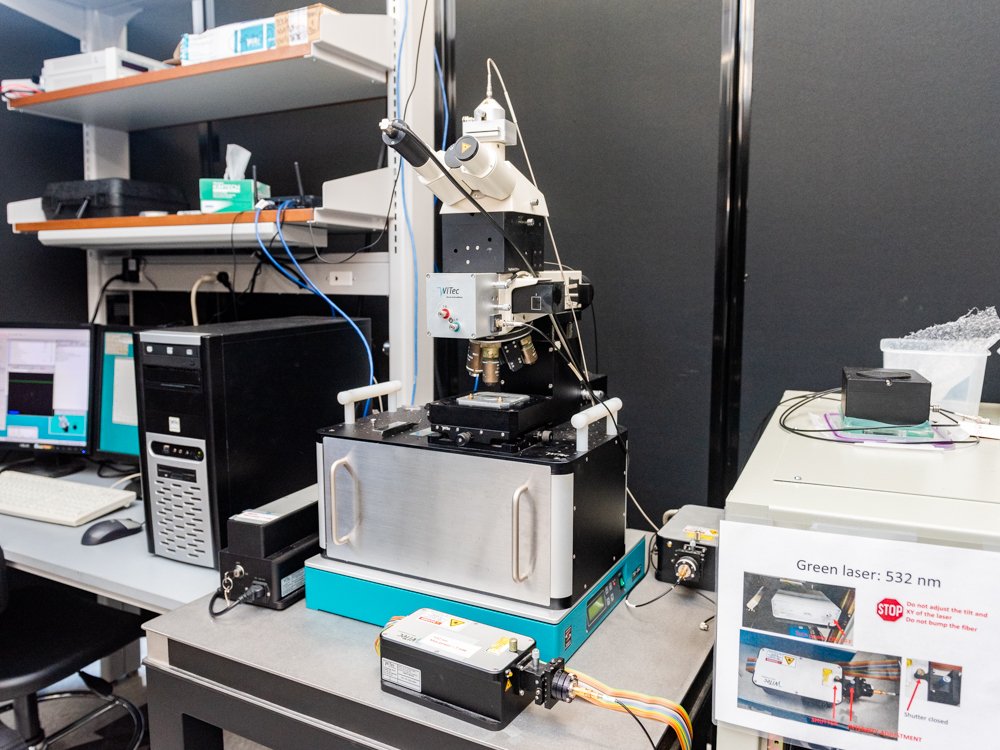

Witec Micro-Raman Spectrometer Alpha 300

Equipment Type:

Micro Raman Spectra

Spectroscopy

Contact: Dr. Andrei Dolocan

Location: EER 6.644

View Details

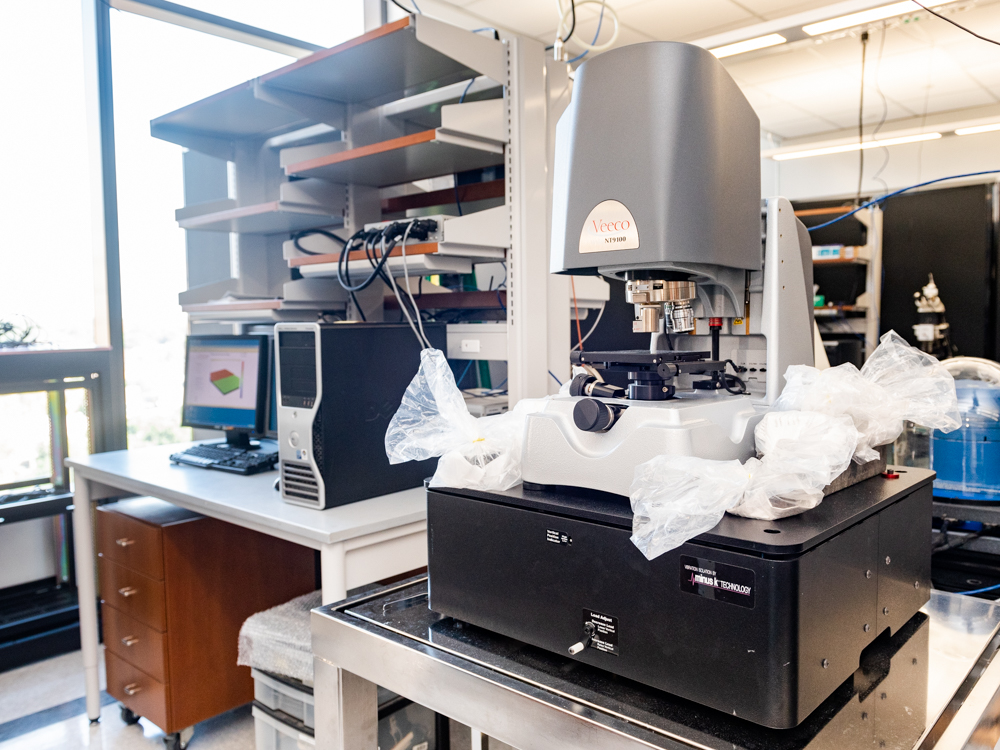

Wyko NT 9100 Optical Profilometer

Equipment Type:

Microscopy/Surface Analysis

Optical Profiles

Surface Analysis

Contact: Dr. Andrei Dolocan

Location: EER 6.628

View Details

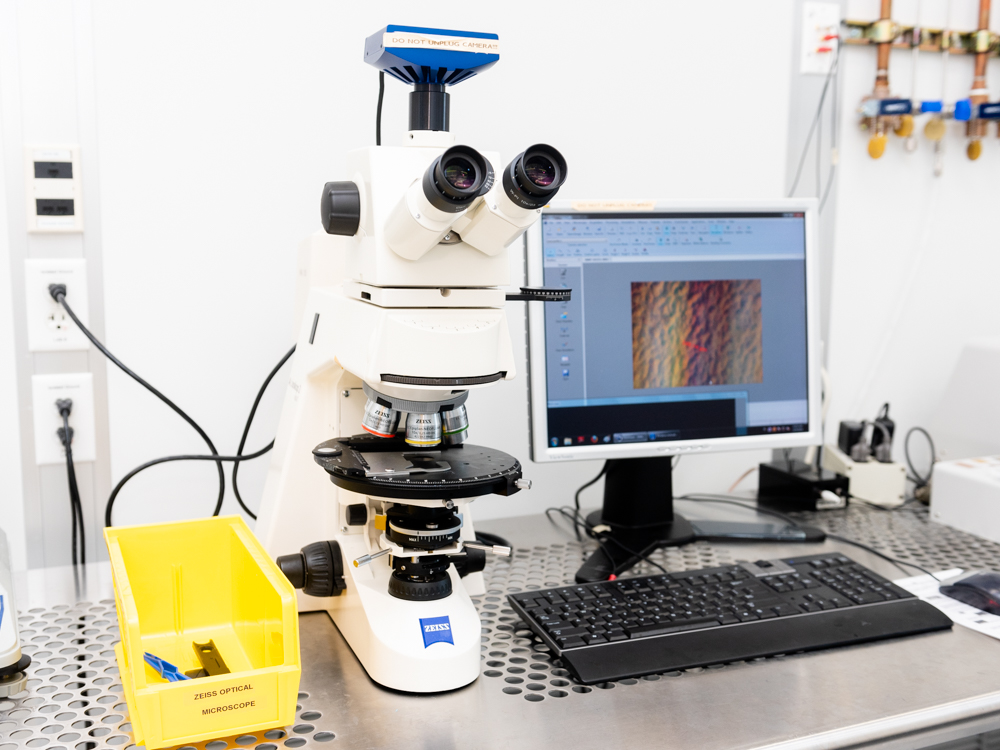

Zeiss Axioscope 2 MAT Optical Microscope

Equipment Type:

Cleanroom Instrumentation

Metrology

Microscopy/Surface Analysis

Contact: Dr. Raluca Gearba

Location: FNT 4.106